Extracting CBG & CBD: How Does it Work?

Written by: Scott Sondles

CBD is currently the most coveted molecule in the hemp industry, but as the market becomes more educated on CBG there will be a shift in the wins. Everything from moisturizing lotion, eye drops, and antimicrobial products will demand CBG isolates or CBG rich hemp extracts. The highest quality cannabinoid products of the future will have a full-spectrum of cannabinoids that includes a healthy dose of both CBG and CBD.

CBG has unique characteristics that will make it a preferred ingredient for many product formulations and products that contain CBG will command a premium. Demand for CBG is building and many companies are trying to position their company to capitalize on the cannabinoid boom that will overtake the CBD market. Extracting CBD has been a lucrative business for many organizations and CBG is expected to demand a much higher price per kilo than CBD.

Buyers are already scrutinizing the quality of hemp oils based on the full-spectrum of bioactive chemicals and hemp extracts that contain higher concentrations of CBG will continue to sell for a premium in the marketplace. If you’re looking to increase the profitability of your hemp processing business then you need to get serious about increasing your ability to extract CBG and other secondary molecules. Some reports suggest that CBG can go for $30,000 to $50,000 per kilo, but this price will naturally drop when more suppliers enter the market.

Raw Material

The first step to extracting hemp for CBG & CBD is securing the raw material that has adequate concentrations of the key cannabinoids. Due to the small levels of CBG or CBGa that are found in mature hemp or cannabis flowers, it becomes much harder to extract and isolate CBG. All CBG originates in the acid form as CBGa and it naturally converts to CBG or other acidic cannabinoids over time. These include THCa, CBDa, and CBCa. Throughout its life and after harvest the chemical profile of cannabinoids is constantly changing. Competitive advantages will be created by the processors that can do the best job of extracting and preserving the rarest of cannabinoids and secondary compounds.

Extraction experts and processing facilities are also increasing their CBG yields by harvesting plants early and processing the raw flowers as quickly as possible. By harvesting early and extracting as quickly as possible the process has the ability to extract and preserve CBG and CBGa before they are converted into downstream cannabinoids. Some processors and growers have found CBG concentrations may be highest in flowering plants that are as young as 6 weeks old.

Breeding High CBG Plants

Finding high CBG hemp genetics is difficult and finding hemp CBG flowers is even harder. The growing awareness around the therapeutic properties of CBG is still in its infancy and as awareness has increased, so has the interest in breeding hemp cultivars that are higher in CBG. The majority of hemp and cannabis strains contain less than 1% of CBG, but some breeders are reporting cultivars that are reaching 10% CBG and with genetic engineering anything is possible. CBG levels should be adequately tested using High Performance Liquid Chromatography (HPLC). The future production of CBG oil will come from the organic farm and regenerative farm fields all across the world.

Whole Plant or Full-spectrum Extract

People are always looking for black and white solutions and answers, but when it comes to the question of whether CBG is ‘better’ than CBD there is no concrete answer and we are still just scratching the surface of what each cannabinoid does in isolation. For more information about the differences between CBD and CBG check out CBG v.s. CBD: What are the Differences.

What we do know is that both CBG and CBD are more effective when they’re working together. Hemp processors and extractors that can do the best job of preserving the full range of cannabinoids and secondary compounds produce the highest quality therapeutics. Many of us that are already using the whole plant, full-spectrum, or broad-spectrum hemp extracts or products may already be consuming CBG along with other minor cannabinoids. The synergistic or entourage effect that is created from all of the cannabinoids working together is difficult and expensive to replicate and some of the best CBG products on the market now are being sold as ‘whole plant’ of ‘full-spectrum’. Enhancing the quality and CBG concentrations of these whole plant extracts thus has more to do with improving cultivar genetics and modifying cultivation methods.

The hyper-focus on isolated cannabinoids like CBD or CBG is believed to be both good and bad. On the one hand Big Pharma and traditional pharmacological researchers have always focused on the purity of compounds and have thus preferred to research isolated compounds. This research is beneficial to the entire hemp and cannabis market as we now have studies that showcase the benefits of CBD v.s. CBG, but in reality our bodies weren’t engineered to thrive solely on one or two isolated compounds. Our endocannabinoid system and g-protein receptors that line our cells are extremely complex and these systems were designed to received messages from a wide variety of internal and external compounds. There are many researchers that believe we are throwing the baby out with the bathwater when it comes to over processing and isolating cannabinoids and often the most effective medicine will be a natural extract that has been minimally processed. The goal of extraction is to preserve the full ‘chemovar’ (chemical fingerprint) of the plant material and for too many cannabis and hemp companies have tunnel vision when it comes to producing isolates and pure compounds. Purity doesn’t mean quality when it comes to cannabis, hemp or natural extracts.

Extraction Process

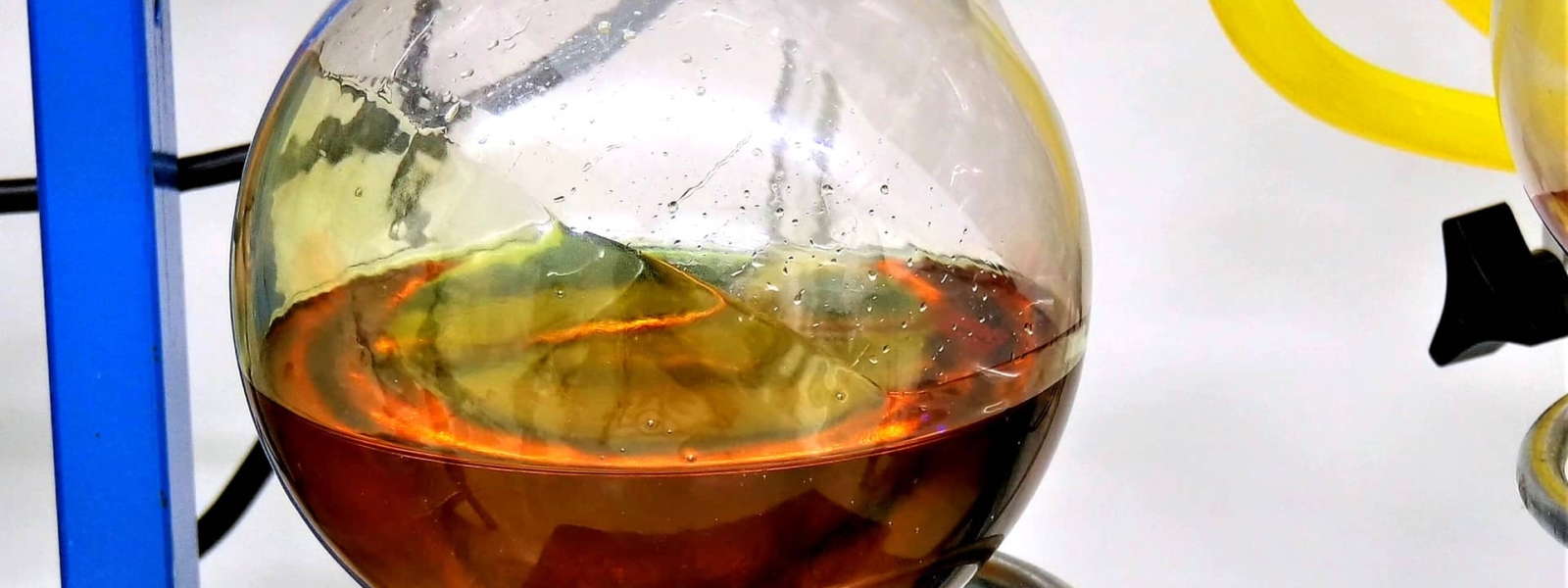

Extracting CBD and CBG are similar processes except that there is a lot more CBD to extract than CBG. With hemp extractions there is typically a crude extraction using supercritical CO2 fluids or ethanol, followed by a series of proprietary post-processing methods to refine and potentially isolate specific cannabinoids.

When comparing extraction methods, supercritical CO2 extraction is the newcomer on the block and it has many advantages over more traditional alcohol extractions. During the main extraction phase, the cannabinoids and bioactive compounds are dissolved in the extracting fluid and then separated from extracting fluid in downstream processes. For supercritical fluids this involves changing pressures and temperatures and for ethanol extraction this involves centrifuges and rotary evaporators to separate ethanol from the extract.

The biggest advantage behind subcritical or supercritical CO2 is its ability to produce raw extracts with no residual solvent behind. Subcritical and supercritical CO2 extraction machines pressurize CO2 gas and at a certain pressure and temperature, the CO2 gas turns into a liquid (subcritical), and eventually, with more pressure, it will reach a ‘supercritical’ phase of matter where it takes on the properties of both a gas and a liquid. A supercritical fluid is when the fluid takes on the properties of both a gas and a liquid. During the liquid or supercritical phase, the CO2 acts as a solvent that has the ability to selectively extract plant compounds based on their molecular weight. Some of the top equipment manufacturers also allow processors with the ability to fractionate their extraction process to preserve the more volatile and lighter molecules called terpenes.

During the separation process, the liquid or supercritical CO2 is pumped from high pressure to low pressure where the CO2 turns back into a gas and the plant compounds precipitate into the collection chamber. With alcohol extraction processors have to deal with the separation of cannabinoids from alcohol which is often a time-consuming and thermally degrading process. Furthermore, if processors are looking to preserve acid cannabinoids such as CBGa then CO2 will provide an advantage due to the low temperatures used. Supercritical CO2 extraction methods are also developing a higher standard for traditional herbal supplements.

Post-processing steps may include the use of distillation, centrifugal, and chromatography equipment. The most common method for creating CBG isolates is chromatography equipment. CBG can also be turned into 100% pure crystals that can be crushed into a powder type substance. Once extracted CBG raw materials and products can be stored at room temperature and away from sunlight.

Synthesizing Cannabinoids in a Lab

CBG compounds are already being used in a handful of personal care products, but the lower concentrations and difficulties that come with separating cannabinoids has created a bottleneck within the industry. Due to this problem one biotech company has actually begun synetiszing CBG from engineered yeast and fermentation techniques. The company claims to be the first CBG molecule that is available on the commercial market and has the ability to produce one ton of CBG per year.

This new biotechnology is fascinating, but it does have its drawbacks when it comes to producing full-spectrum cannabinoid profiles and it’s environmental carbon footprint. The natural fermentation process that is utilized produces CO2 while outdoor hemp and cannabis cultivate sequester CO2. Furthermore, researchers are beginning to understand the the highest quality cannabinoid medications have a full-spectrum of cannabinoids and bioactive compounds, not just CBG. When extracting and isolating CBG cannabinoids from raw plant material the processor also has the ability to harvest CBD, THC, minor cannabinoids, and aromatic terpenes. Many people believe that synthesizing cannabinoids in laboratories will allow for the development of ‘designer’ cannabinoid formulas, but there are many other researchers that believe this route will be too costly when it comes to recreating what nature has already perfected.